Description

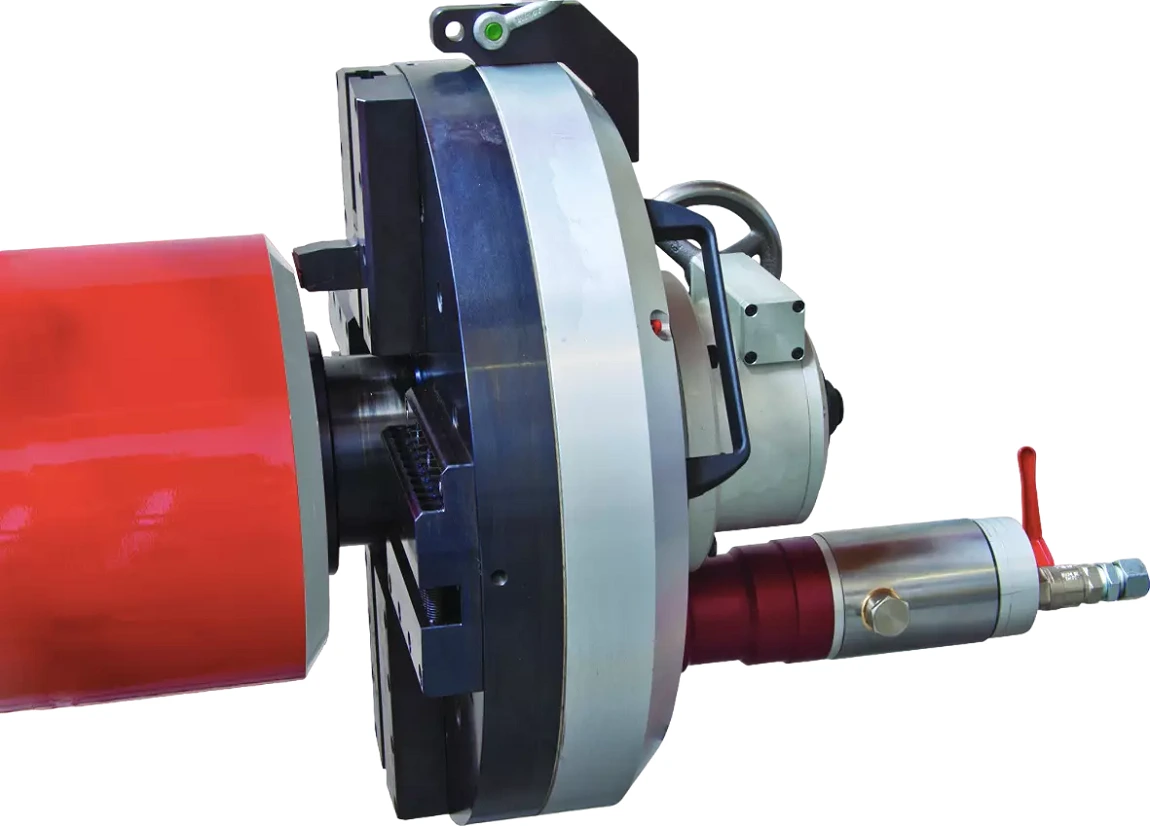

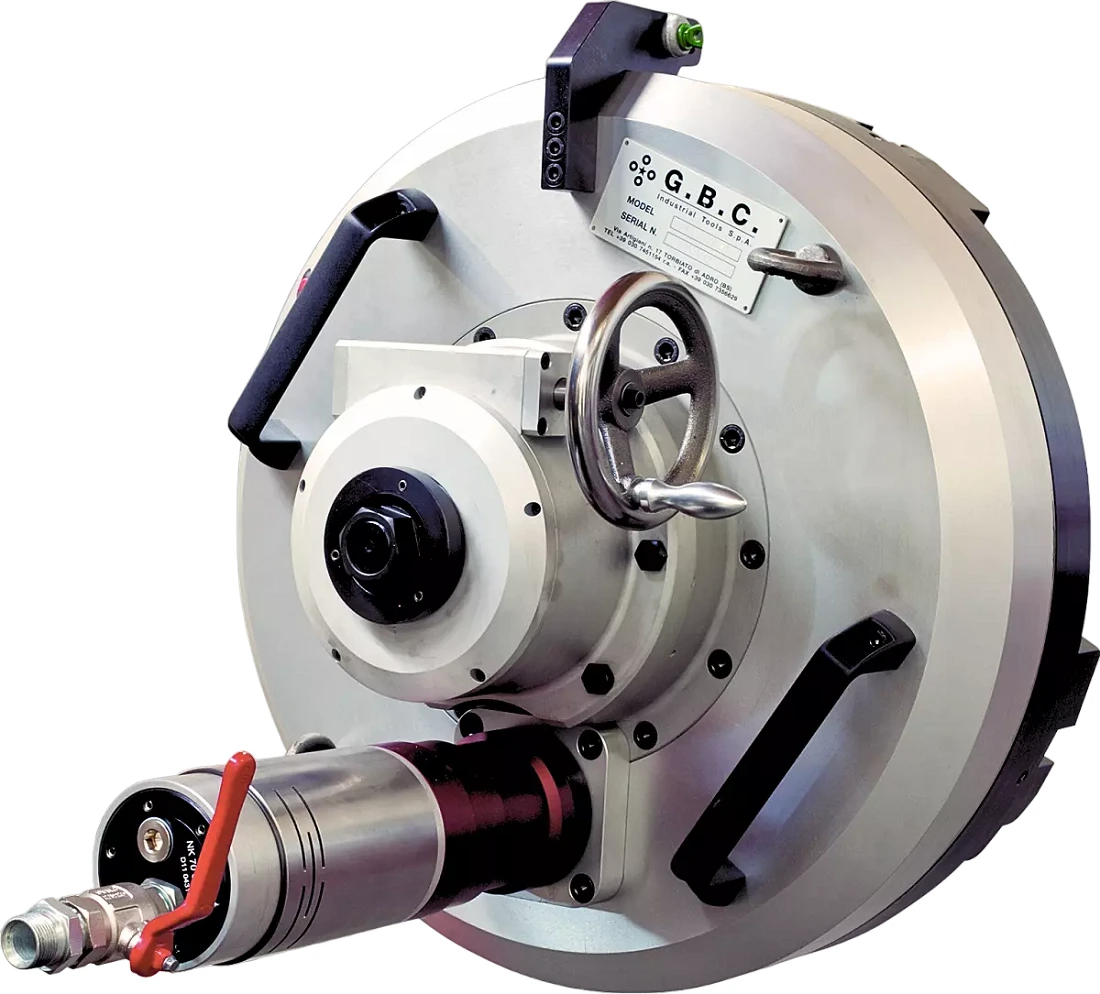

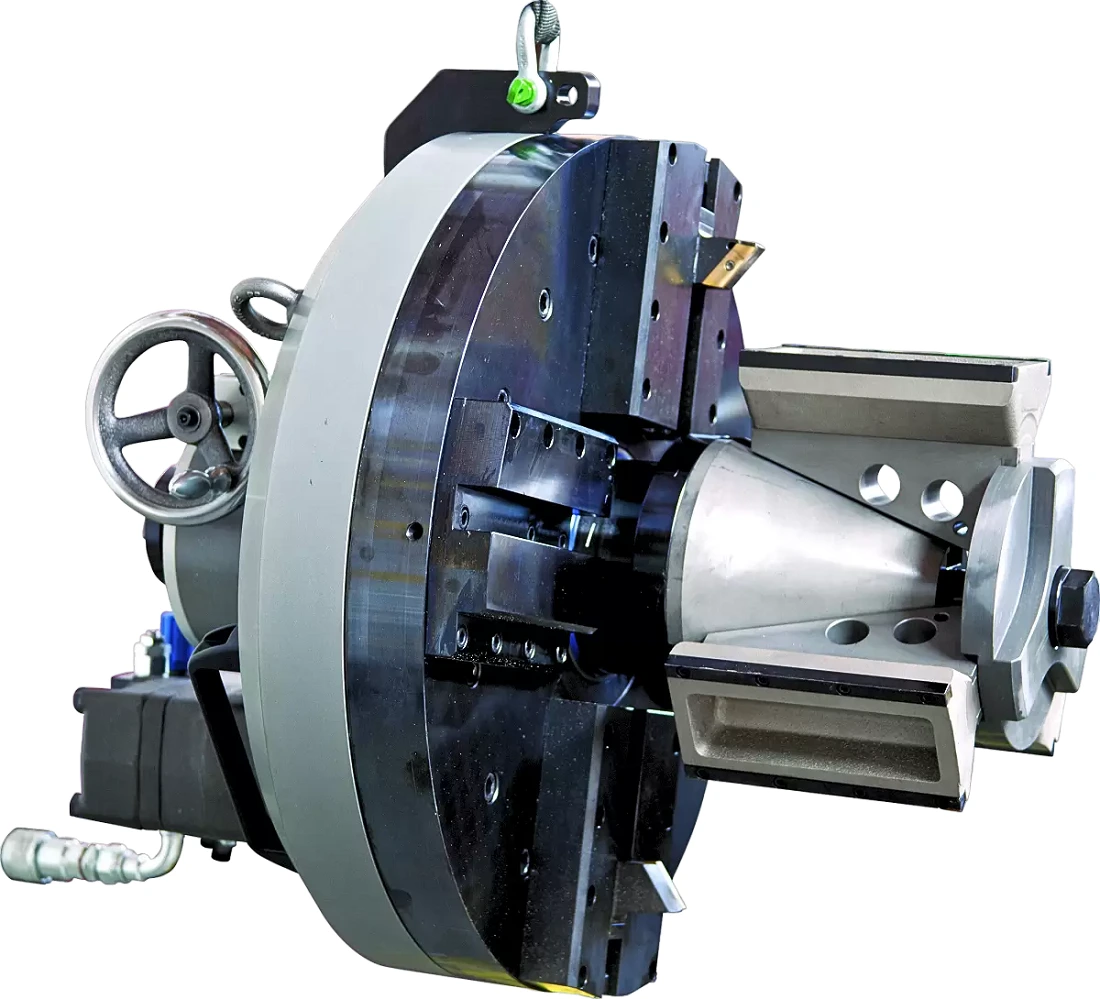

Portable pipe beveling machine SUPERMAXI 7_24

Range ØI 180-504 mm (7,08″ – 19,84″)

This pipe beveling machine Supermaxi 7_24 is designed for piping industries and welding workshops for processing pipelines, boilers and fittings.

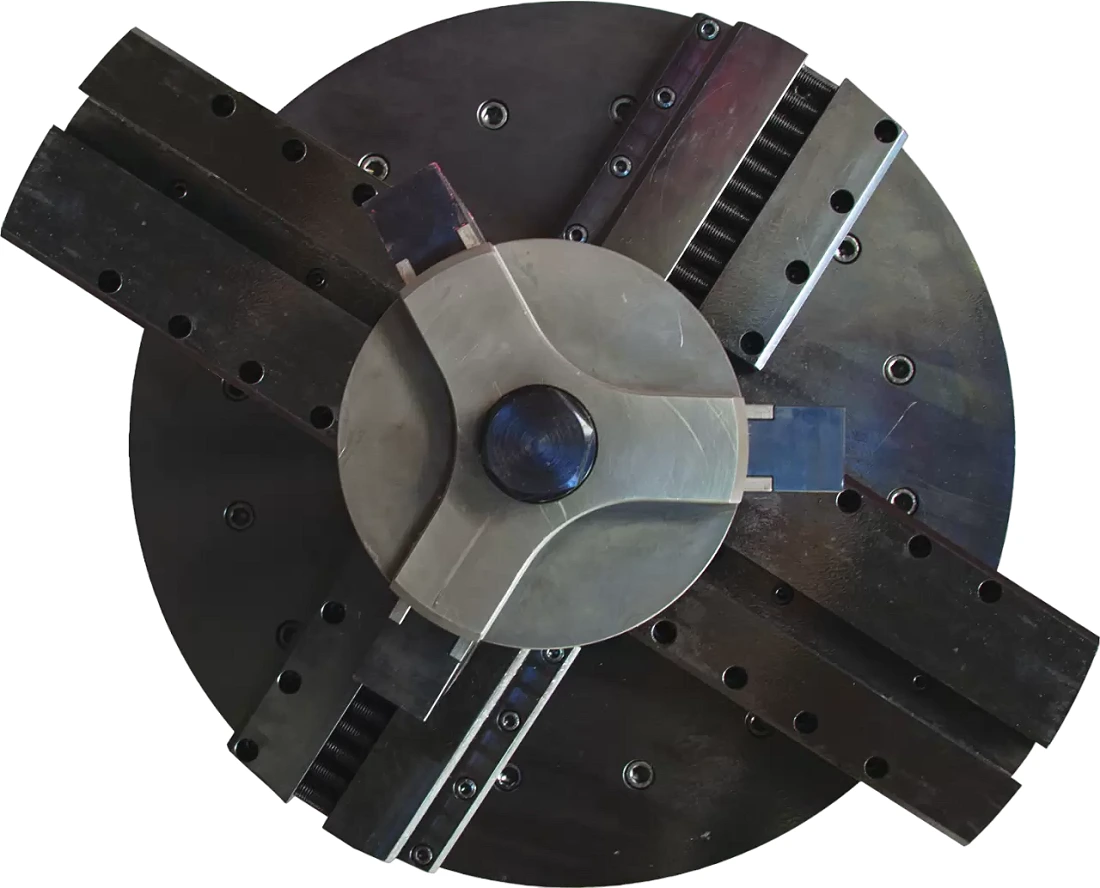

The Supermaxi 7_24 is equipped with a 6 points of contact locking system able to grant stability and absence of vibrations during the operations. Furthermore, the installation and centering are extremely easy, precise and functional.

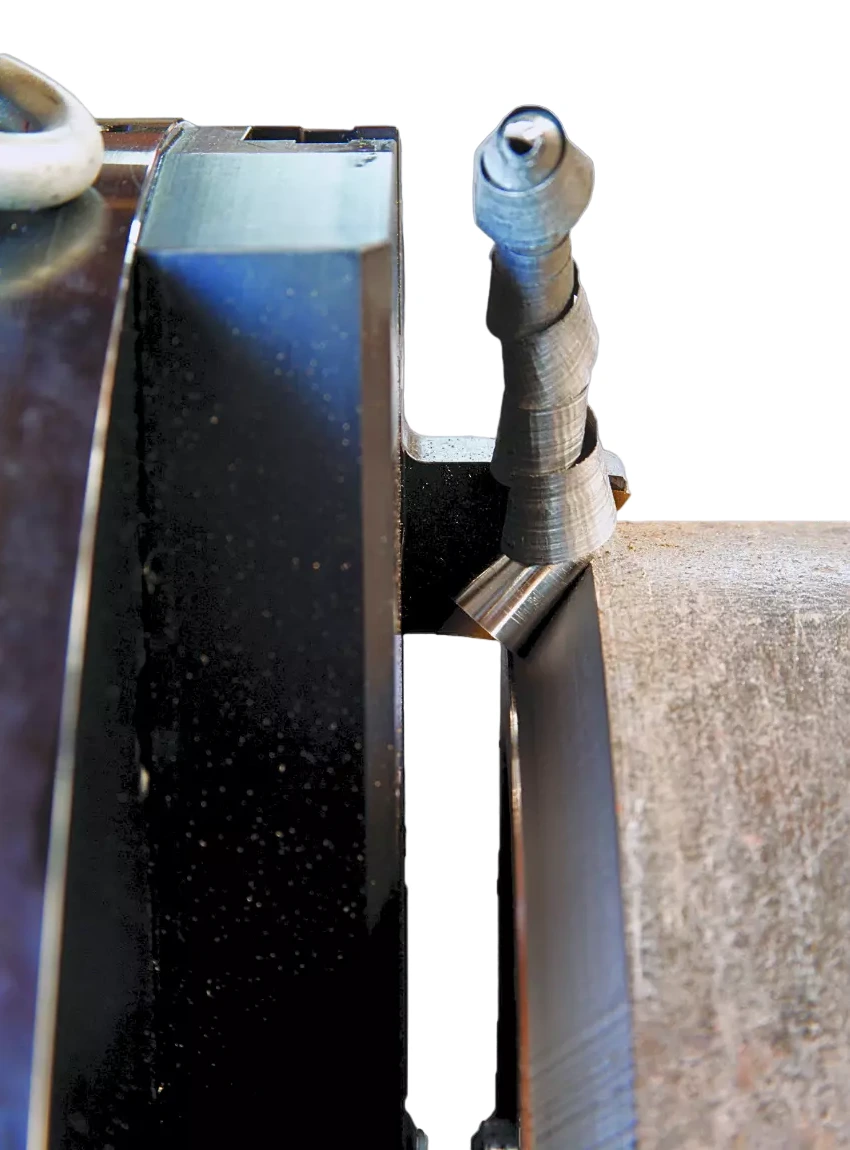

The mandrel of the pipe beveling machine Supermaxi 7_24, thanks to an innovative design, allows the use of standard solid body tools but also wedge locking tools with interchangeable inserts (both interchangeable with those of the model Hypermaxi 20_40). The machine layout is designed so that the chips of the previous pass will not affect the following passes.

With an optional kit, the range of the machine can be extended up to 24″ (609,6 mm) OD.

The pipe beveling machine Supermaxi 7_24 is available in pneumatic, hydraulic or electric versions.

MACHINE FEATURES

RANGE:

Working range from 7” to 20” (180-504 mm) in standard configuration and up to 24” (609,6 mm) with the optional extension kit.

FUNCTIONS:

Milling processes, external and internal tapering, external and internal beveling of pipes.

MATERIALS:

Carbon steel, stainless steel, duplex, inconel, others.

POWER:

Pneumatic, hydraulic or electric.

Supermaxi 7_24 – Pictures

The supermaxi 7_24 pipe beveling machine is ideal for the Oil&Gas sector and on pipes of significant thicknesses, designed for the oil sector and in on-site, offshore, nuclear construction sites and other applications where precision welding is required.

This beveling machine works well on elbows, has a pneumatic locking device and is very robust, which makes it suitable for heavy work.

The pipe beveler has jaws with increased geometry to guarantee a very resistant locking inside the pipe.

Thanks to the new feeding system and two new motors, the uniformity of the pipe beveler’s pass is guaranteed, with a constant radial speed and minimal roughness.

Our pipe milling machine can use easily interchangeable tools to create chamfers of any shape and angle.

he unit is equipped with easily interchangeable tools for any angle of bevel which come in various hardness scales in relation to the material typology:

– 8% cobalt;

– titanium coated;

– tip of hard metal.

Contact us if you are interested in the Supermaxi 7_24 machine or would like to receive a free quote.